Cutting and grinding wheels are abrasive tools used in manufacturing and metal fabrication to cut or remove material from workpieces. They are made of abrasive grains that are bonded with resin and fillers to form a solid disc or wheel.

Why Choose Us

Variety of Products

We can provide a variety of abrasive equipment, including semi-automatic flap disc machines, fully automatic flap disc machines, fully automatic flexible flap disc machines, automatic abrasive slitting machines, etc. We can also provide flap disc raw materials such as glue and backing.

Recognized by Many Parties

Well-known brands Saint-Gobain, 3M, Abrasive and Pferd choose our abrasive equipment to produce flap discs or wheels, cutting and grinding wheels. At the same time, our abrasives have passed CE standard certification.

Rich Production Experience

With over 10 years of experience working with abrasive manufacturers large and small, we can specify, design, source and install the perfect machine for almost any application. No matter what kind of flap disc/ wheel forming, cutting and grinding wheel & packaging machinery, we can manufacture it based on our rich experience.

Strict Quality Standards

All suppliers of raw materials and purchased parts are jointly screened and regularly evaluated by the procurement, technology, and quality control departments to ensure that the raw materials are qualified. Our quality management is a combination of comprehensive employee participation and full value chain quality management from customers to suppliers.

Grinding wheels are discs that contain abrasive particles and grains that have been bonded together to form a wheel shape. Although the disc format is the most common shape, they can also be made in the shape of cones or cups.

Grinding wheels are attached to grinders or saws and rotated at high speeds for a variety of tasks. The abrasive grit and grains in the wheel are able to grind or cut through hard materials such as metal or steel. The abrasive grains are bonded together by either organic or inorganic substances.

Inorganic grinding wheels are fitted in a furnace and have a hard yet brittle structure that holds its form during precision cutting. These wheels usually require dressing before use to straighten the wheel or to form it into a desired shape.

Organic grinding wheels are cured at low temperatures, are shock resistant and do not require dressing. They are commonly used for cutting or grinding work that does not need to be precise.

They are categorised according to characteristics such as grit size, the bonding used, the abrasive material, the grade of the grinding wheel and the wheel's structure.

Types of Grinding Wheels

There are various types of grinding wheel, each with its own type number. The booklet 'Safety in the use of abrasive wheels', produced by the Health and Safety Executive (HSE), lists 33 different types of grinding wheels. In general, six of them are commonly used:

Type 1 – Straight

Type 2 – Cylinder

Type 4 – Tapered

Type 6 – Straight cup

Type 12 – Dish

Type 13 – Saucer

What are Grinding Wheels Used For?

Straight grinding wheels are usually used in bench grinders

Cylinder grinding wheels are used in horizontal or vertical spindle grinders to make flat surfaces

Tapered grinding wheels are wider in the centre with a surface that tapers outwards. These wheels are used to grind gear teeth or threads

Straight cup grinding wheels are fitted to cutter machines and used to sharpen tools or to make flat surfaces

Dish grinding wheels are thin with a flat centre that is raised outwards on the edge. These wheels are commonly used to cut openings such as slots

Saucer grinding wheels have a straight edge section and are used for twist mills and grinding cutters

Cutting wheels, also known as cut-off wheels, typically make narrow, precise cuts into a material at 90° angles. Cutting wheels cut into a material, as opposed to abrasive grinding wheels that grind large pieces of material off a workpiece from a shallow angle. Cutting wheels differ from grinding wheels in both their function and their structure. The largest advantage to using a cutting wheel and angle grinder is that they are easily configured to cut when needed.

Which Cutting Wheel, when?

.045 cutting wheels are designed specifically for cutting metal and have a much thinner thickness (known as "Kerf") than grinding wheels (1/4") and pipeline wheels (1/8"). This is because grinding and pipeline wheels are designed primarily for grinding metal as opposed to cutting. The added thickness of a grinding wheel makes it difficult for cutting jobs, as the user would need to remove more material in a cut, leading to frustration and a longer, less efficient cutting time.

.045 Wheels: .045 wheels are the best choice for efficient cutting. Note that .045 wheels should never be used for deburring metal after cutting or grinding, as this type of misuse could result in wheel failure and in severe injury.

.090 Wheels: .090 wheels are designed for cutting and notching metal. Notching is a shearing process during which a metal scrap piece is removed from the outside edge of a metal workpiece prior to welding.

.095 Ultimate Combo Wheels: Most versatile cutting wheel is the featuring a .095 thickness. This unique thickness of this abrasive wheel allows operators to cut, notch, deburr, and light grind without the need to change the wheel.

There Are Two Basic Configurations Of Cutting Wheels:

Type 1 / Type 41: This is a flat cutting wheel that allows for a maximum depth of cut. The main disadvantage of using a Type 1 wheel is that they mount closer to the guard making it more difficult for the user to see what they are cutting.

Type 27 / Type 42: Originally developed and patented by United Abrasives, this design features more of a rigid feel while cutting, enhanced operator visibility of the cut, and the ability to flush cut (as the raised hub allows for the locking nut to be recessed).

Abrasive Grains

Abrasive grains are hard, sharp materials that can be used to wear away another material when one or the other is moved in pressurized contact. The most widely used abrasive grains include:

Aluminum Oxide: The most common and popular abrasive used in grinding wheels, aluminum oxide is the grain of choice for grinding high speed steel, carbon steel, alloy steel, annealed malleable iron, wrought iron, bronze and most metals. Aluminum oxide typically has a lower initial cost for the user, and delivers very good cut rates and reliable durability.

Ceramic Aluminum Oxide (Alumina Ceramic): This industrial synthetic grain fractures at a controlled rate at the submicron level, constantly creating thousands of new cutting points. Exceptionally strong, ceramic aluminum oxide is primarily used for precision grinding and high performance applications on steels, alloys, and hard-to-grind materials. Ceramics also tend to cut cooler, minimizing discoloration while maximizing product life.

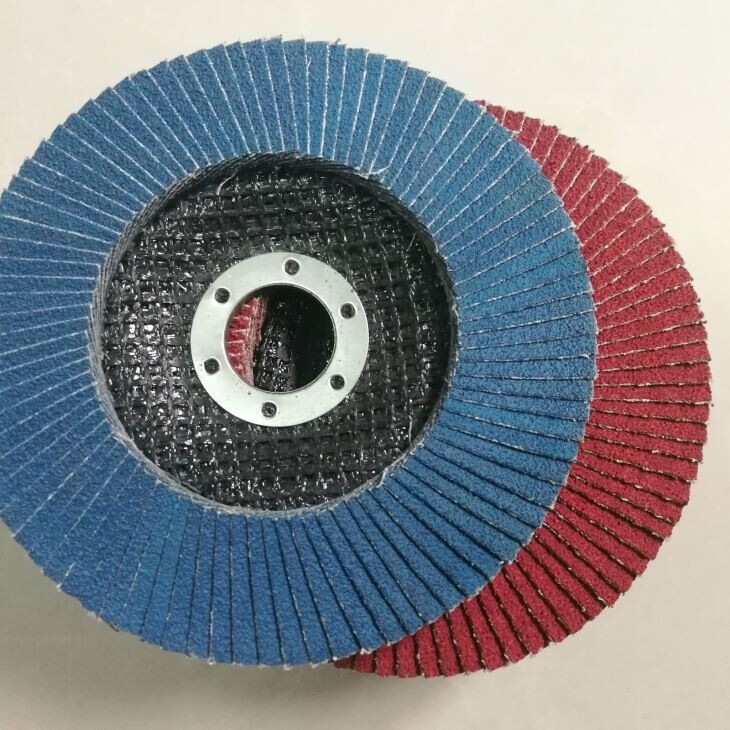

Zirconium (also known as Zirconia Alumina or Zirc): Made from a mixture of both aluminum oxide and zirconium oxide, this tough abrasive grain works well in high performance grinding applications, including cut-off operations, on a broad range of steels and steel alloys. Zirconium grain has an extremely durable design that allows long life and a low cost-per-cut ratio.

Cut-off Wheel vs Grinding Wheel: Differences Between them?

Cutting wheels or cut-off wheels have different applications and structures than grinding wheels.

Cut-off wheels cut small material workpieces at 90-degree angles, whereas grinding wheels grind large material workpieces from a low angle. As a result, cut-off wheels are quite thinner than grinding wheels. Cut-off wheel thinness provides more clean, and accurate cuts.

Cut-off wheels are used for cutting on the peripheral surface. Why?

Cut-off wheels are thin, so not preferable for side cutting.

The fiberglass reinforcing adds strength to the cutting wheel. Do not use the side of the wheel this can damage or break the wheel.

Grinding must only be done on the surface of the wheel. But, when it comes to edge grinding, using a cut-off wheel can be risky. It can break the wheel when use side for deburring or grinding. The workpiece has the potential to cut through the reinforcing side fiberglass, causing the wheel to deteriorate. The thin cut-off wheels cannot resist heavy sideload, whereas the thicker grinding wheels can resist against powerful sideload.

The grinding wheel is thicker than a cut-off wheel. 4 1/2 inch metal grinding wheel is considered ideal for fast stock removal with long service. An abrasive bonded grinding wheel must be at least 1/4″ thick.

Choosing Cut-off wheels and Grinding wheels

Consider all the factors such as Abrasive grain, size, shape, and material are important factors when choosing the best cut-off wheel or a grinding wheel.

The ideal selection of cut-off wheel and grinding wheel depends on the type of metal you are cutting. When compared to the smaller or thin workpiece, thick metal sheets require more powerful grinding wheels.

Our Factory

Our company is a high-tech enterprise that independently designs, develops, produces, and sells automatic abrasive flap disc production lines. Our flap disc machine All touch digital operation, simple and quick, user-friendly, the main modules of our machine use CNC machining center integrated precision milling, the main motor is Japan Panasonic, the cylinder uses Air TAC, the sensor uses Autonics, PLC use Delta, all of these configurations ensure that our equipment can work stably and efficiently, producing 6,000 Pcs per day for 8 hours. Professionalism, focus, bring you a best abrasive machine.